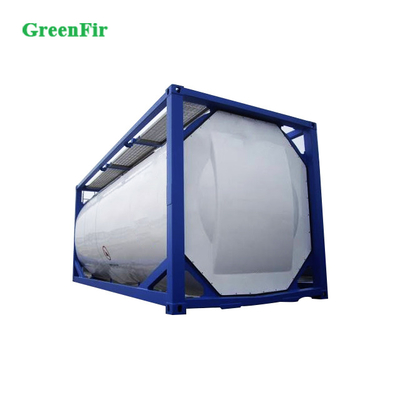

With the widespread use of LNG in recent years, the use of tank containers in the LNG industry is also booming. Compared with traditional LNG carriers and natural gas pipelines, tank containers have the characteristics of convenient transportation, small investment, short investment period, and low maintenance cost. More and more customers have chosen to use ISO tank containers to transport LNG.

The use of ISO tank containers to transport LNG can directly rely on the existing container transportation network to achieve a mode of intermodal transportation between roads, railways and water transport. After unloading, the tank containers are directly delivered to the customer terminal site for use. Out of the advantages of fast and efficient, especially in areas where reception facilities are lacking, tank container transportation has become the only choice for LNG supply.